Pressure Equipment Engineering Services, Inc. has extensive experience in design, analysis and re-rating of Pressure vessels used in refineries, chemical plants, power plants, nuclear plants and other processing facilities. Some of the capabilities of PEESI in the area of pressure vessels are listed as follows:

- Pressure Vessels Design and analysis(Tall Columns, Vertical Pressure Vessels, Horizontal Pressure Vessels, Spherical Vessels, Reactors etc.) based on ASME Boiler & Pressure Vessel Code, Section VIII, Division . – 1, Division. – 2 and Division. – 3.

- Analysis of Power Boilers per ASME Boiler & Pressure Vessel Code, Section-1

- Calculations for repair and alteration of existing Pressure Vessels per API-510 and National Board Inspection Code.

- Calculation of minimum retirement thickness values for existing pressure vessels / pressure vessel components to maximize the remaining safe and useful life.

- Re-rating of pressure vessels for a new set of design parameters.

- Calculations to check the suitability of vessels for in-situ PWHT.

- Fitness-for-service evaluations for pressure vessels to assure the structural integrity of equipment for the intended design parameters and to offer life extension considerations.

- Fatigue analysis to calculate the fatigue life of pressure vessels subjected to pressure cycles, temperature cycles and startup / shutdown cycles.

- Failure Analysis to identify the root cause of failure for the failed pressure vessels or pressure vessel components.

- Finite Element Analysis for pressure vessels and pressure vessel components.

- Pressure vessel certification, calculations and rating / re-rating for pressure vessels that do not contain sufficient design information in their files.

- Design of Structural systems and supports for continued operation of leaked vessels or vessels that violate the minimum required thicknesses based on structural considerations.

- Evaluation of cracks and Flaws in pressure vessels by applying Fracture Mechanics techniques.

- Evaluation of Minimum Safe Operating Temperature (MSOT) for existing vessels which do not meet the current MDMT requirement of the ASME Code.

- Evaluation of Pressure Vessels after accidental over-pressurization.

- Discontinuity Analysis for Pressure Vessels involving special situations of Structural and Material discontinuity.

- Analysis to assure Mechanical Integrity of Pressure Vessels for following type of flaws: Generalized corrosion, Localized corrosion / Thinning, Blisters, Laminations, Bulges, Gouges, Dents, Cracks etc.

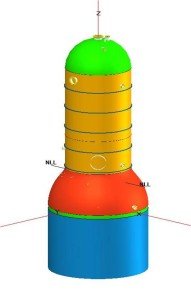

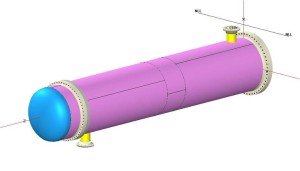

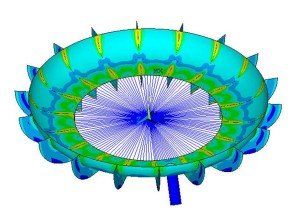

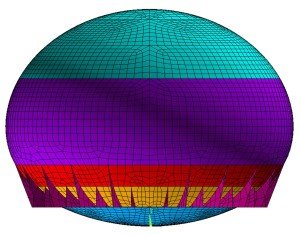

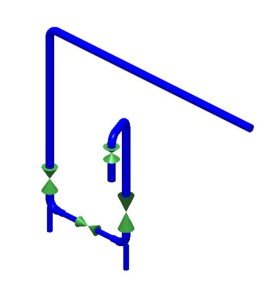

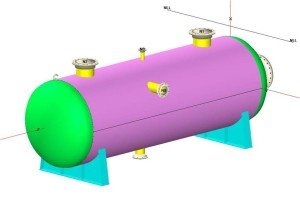

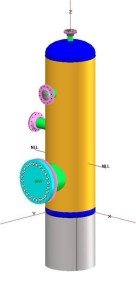

Here are some examples of Pressure Vessel Design / Analysis performed by Pressure Equipment Engineering Services, Inc.