A few examples of Heat Exchangers Design / Analysis performed by Pressure Equipment Engineering Services, Inc. are as follows:

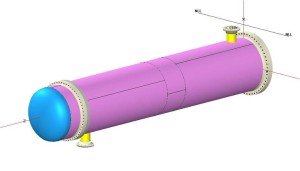

- Fitness for service evaluation was performed for a fixed tubesheet heat exchanger with flanged and flued expansion joint. The shell side of the exchanger had significant corrosion. The original shell side design parameters were 100 psig @150 °F and the original tube side design parameters were 50 psig @ 225 °F. The request was to see if both sides of the exchanger would be suitable for 600 °F. As a result of the significant corrosion on the shell side of the exchanger, the heat exchanger did not meet the TEMA thickness requirements. However, when mechanical integrity evaluation was performed, the exchanger was found to be fit-for-service satisfying ASME Section VIII, Div.- 1 requirements. It was also found that when both shell and tube side design temperatures are 600 °F, the thermal stresses are well above the code allowable stresses. After several iterations, it was found that the acceptable thermal stress levels can be achieved when the tube side design temperature is lowered to 520 °F. Hence, the heat exchanger was declared fit for service with the final shell side rating of 100 psig @ 600 °F and the final tube side rating of 50 psig @ 520 °F.

- The shell side of the heat exchanger CE-13 was to be re-rated from 125 psig @750 °F to 150 psig @ 750 °F. The shell side of the heat exchanger was modeled and analyzed using the software COMPRESS.The shell, head and nozzles were found to be adequate for the new design parameters.

The shell flanges and the flange that connects to the stationary tubesheet were also found to be adequate for the new design parameters.The inlet nozzle was connected to the shell side using a vapor belt. This vapor belt had radial plates and an annular plate. This was analyzed separately and was found to be adequate for the new design parameters. The minimum thickness values were specified for all the shell side components. This was done to ensure that we have adequate corrosion allowance for the future operation of the shell side of the heat exchanger.Based on the above engineering evaluation, all the pressure components of the shell side of the heat exchanger CE-13 were re-rated to the new MAWP of 150 psig @ 750 °F.The following additional recommendations were made before the re-rating was considered valid:

As the shell side of the exchanger was being re-rated for higher MAWP, the shell side of the heat exchanger must be hydrotested to a pressure of 245 psig @ 70 °F.

It is highly recommended that the pressure relief system associated with this heat exchanger must be evaluated and modified for any changes in the pressure relief scenario caused by the higher MAWP of the shell side.