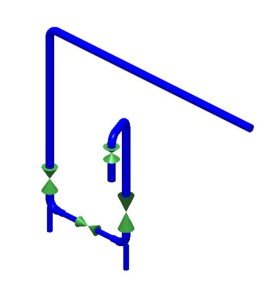

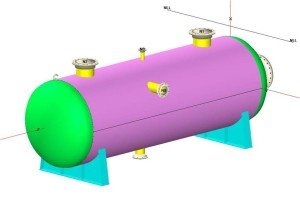

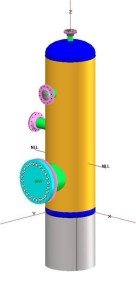

Pressure Equipment Engineering Services, Inc. has following capabilities in the area of Piping, Design / Analysis:

- Piping Stress Analysis and piping flexibility calculations for new piping systems for code compliance issues.

- Piping Stress Analysis and piping flexibility calculations for existing piping systems for code compliance and fitness-for-service evaluation issues.

- Design, analysis and re-rating of piping systems based on ASME/ANSI B31.3. Inspection, repair, alteration and re-rating based on API-570.

- Design, analysis and re-rating of piping systems based on ASME/ANSI B31.1. Inspection, repair, alteration and re-rating based on API-570.

- Evaluation of piping systems to address piping vibration problems.

- Fitness-for-service evaluation of piping systems to calculate MSOT (Minimum safe operating temperature) and address brittle fracture considerations.

- Evaluation of piping systems for correcting / re-specifying pipe supports to address over stressed piping or piping with inadequate pipe supports or restraints.

- Fitness-for-service evaluations for piping systems to assure the structural integrity of piping for the intended design parameters and to offer life extension considerations.

- Fatigue analysis to calculate the fatigue life of piping systems subjected to pressure cycles, temperature cycles and startup / shutdown cycles.

- Failure Analysis to identify the root cause of failure for the failed piping or piping components.

- Finite Element Analysis for piping and piping components.

- Evaluation of piping systems to address piping issues that do not meet the original design intent of the piping or piping is subjected to new design parameters. Some typical piping problems may be distortion of high temperature piping, piping lifting off the intended supports, piping with large thermal growth but no expansion loops present, piping with inadequate restraints or piping not functioning correctly because of differences in original piping model and the field installed piping.

- Analysis to assure Mechanical Integrity of piping systems for following type of flaws: Generalized corrosion, Localized corrosion / Thinning, Blisters, Laminations, Bulges, Gouges, Dents, Cracks etc.

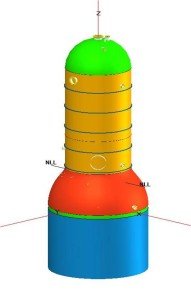

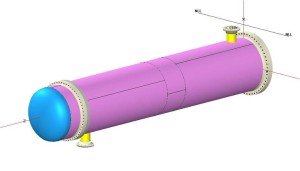

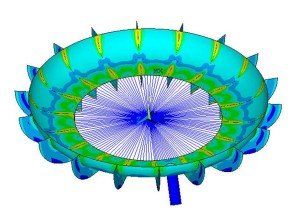

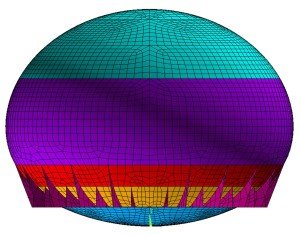

Here are some examples of Piping Design / Analysis performed by Pressure Equipment Engineering Services, Inc.