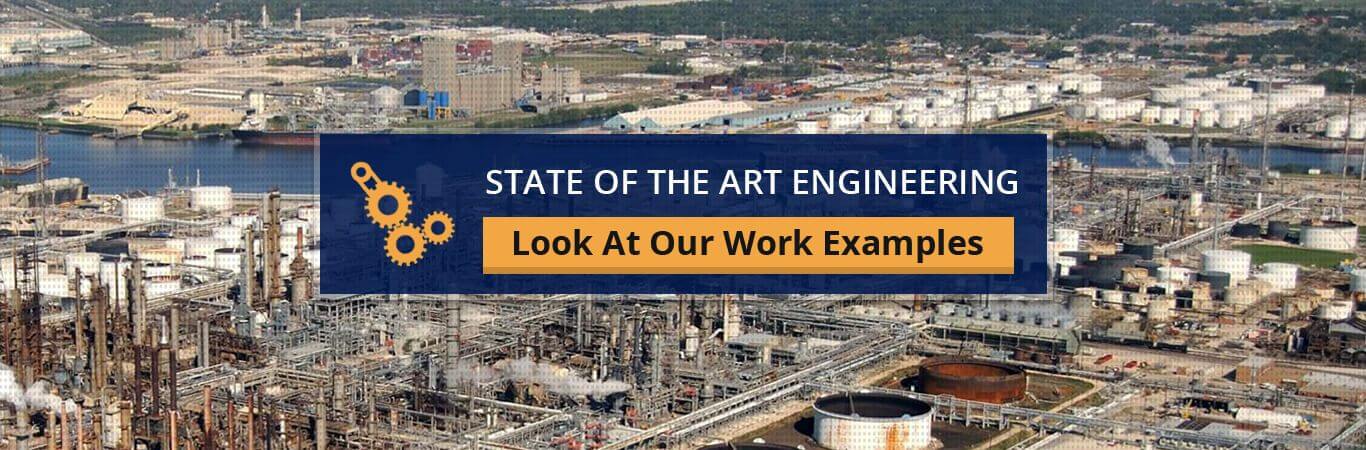

Pressure Equipment Engineering Services, Inc. provides a wide range of mechanical and structural engineering services for petroleum refineries, chemical plants, petrochemical plants, pharmaceutical plants, food processing plants, cement plants, pulp & paper plants, fossil power plants and nuclear power plants.

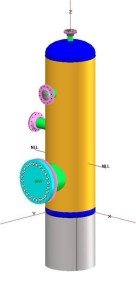

We specialize in design, analysis, re-rating and fitness-for-service evaluations of pressure vessels, heat exchangers, storage tanks and piping.

We provide high quality engineering services at low cost. We guarantee that our services represent the best possible value for engineering services. We have a wide range of engineering tools to address any of your engineering needs for analysis and design of Pressure Vessels, Heat Exchangers, Boilers, Storage tanks and Piping. We are the preferred choice for an increasing number of companies due to our high quality performance and quick response time.

Consulting Services:

Pressure Equipment Engineering Services, Inc. provides a wide range of mechanical and structural engineering services for Design, Analysis, Re-rating and Fitness-for-service evaluations of following Pressure Equipment.

Read More

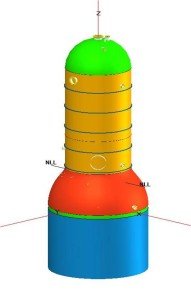

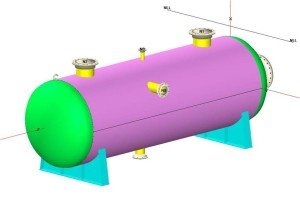

Pressure Vessel Design / Analysis / Re-Rating:

We have the expertise to perform analysis and re-rating of the pressure vessel for a new set of design parameters. The re-rating can be due to higher design pressure or higher design temperature for the existing pressure vessel.

Read More

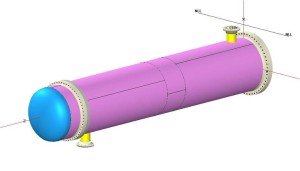

HEAT EXCHANGER DESIGN / ANALYSIS / RE-RATING:

We analyze and re-rate heat exchangers based on TEMA and ASME Boiler & Pressure Vessel Code, Section VIII, Div. – 1.

Read More

Fitness for Service Evaluations:

We perform Fitness for Service evaluation to ensure safe and reliable operability of pressure equipment.

Read More

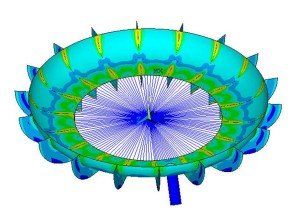

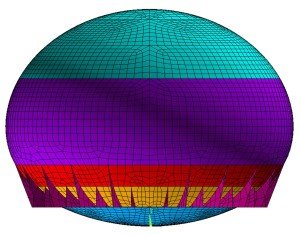

Finite Element Analysis:

Finite Element Analysis (FEA) is a technique that provides the numerical solution of a complex problem for which no closed-form solution exists. We have the expertise and cutting edge tools to solve these engineering problems quickly and efficiently using FEA.

Read More

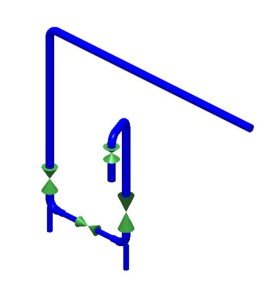

Piping Stress Analysis:

We perform stress analysis of piping used in various processing facilities using the industry standard software CAESAR II.

Read More

Minimum Retirement Thickness Calculations:

The minimum retirement thickness values for existing pressure vessels and pressure vessel components are calculated to maximize the remaining safe and useful life. We perform calculations to specify minimum retirement thickness values for various pressure components.

Read More

PRESSURE EQUIPMENT CERTIFICATION:

When the documentation in equipment files is not adequate to determine its operating or design parameters, the equipment needs to be reverse engineered to calculate its MAWP / Design parameters while satisfying all the applicable code rules. This is called Pressure Equipment Certification. We provide this service to make you OSHA compliant.

Read More