When the documentation in equipment files is not adequate to determine its operating or design parameters, the equipment needs to be reverse engineered to calculate its MAWP / Design parameters while satisfying all the applicable code rules. This is called Pressure Equipment Certification. This whole process is explained below.

There are many situations when the plant has lost the necessary files for a pressure equipment. The key information is equipment drawings, equipment calculations, U-1 form etc. This missing information makes the plant out of compliance with OSHA rules. There is an OSHA rule that states that the plant operator shall maintain the necessary documentation in the equipment file to determine its operating and design parameters. Clearly, the missing documentation is a violation of OSHA rules.

To make the plant OSHA compliant, it is required that the plant should re-generate the equipment calculations and Substitute U-1 form and maintain all the key information in the files. By doing this for all the equipment with missing information, the plant can avoid the fines and penalties imposed by OSHA.

Pressure Equipment Engineering Services, Inc. helps you generate the equipment calculations and Substitute U-1 form. This is based on the information collected about the equipment. This includes equipment dimensions, equipment inspection data, photographs, material information etc. Sometimes, this may also require material testing, material verification and other detailed metallurgical information. When the plant provides all the relevant information to us, we perform reverse engineering to calculate the MAWP etc. for the pressure equipment and generate the equipment calculations and the Substitute U-1 form. This information is saved in the plant equipment files and a nameplate with the maximum MAWP is attached to the equipment. This completes the process of Pressure Equipment Certification.

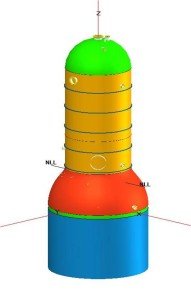

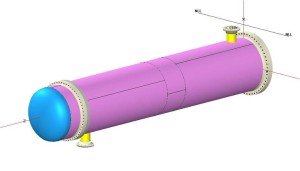

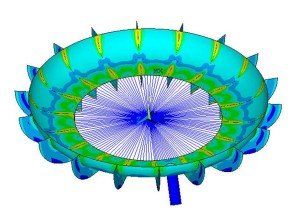

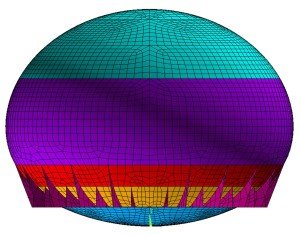

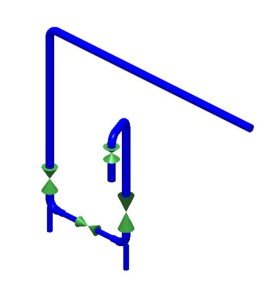

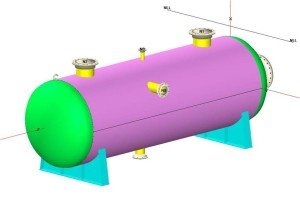

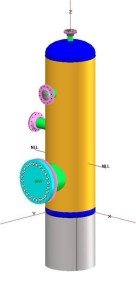

Here are some examples of Pressure Equipment Certification performed by Pressure Equipment Engineering Services, Inc.