Pressure Equipment Engineering Services, Inc. has following capabilities in the area of Heat Exchangers:

- Design and analysis of Heat Exchangers based on TEMA and ASME Boiler & Pressure Vessel Code, Section VIII, Div. – 1.

- Calculation of minimum retirement thickness values for existing heat exchangers / heat exchanger components to maximize the remaining safe and useful life.

- Calculations for repair and alteration of existing heat exchangers.

- Calculations for tubesheet thicknesses for various type of heat exchangers.

- Calculations for other heat exchanger components e.g. Channel covers, floating heads etc.

- Calculations for Fixed tubesheet heat exchangers (with or without flanged and flued expansion joints) for re-rating and fitness-for-service evaluation.

- Fitness-for-service evaluation of Heat exchangers to calculate Minimum safe operating temperature (MSOT) for existing heat exchangers which do not meet the current MDMT requirement of the ASME code.

- Re-rating of heat exchangers for a new set of design parameters.

- Fitness-for-service evaluations for heat exchangers to assure the structural integrity of equipment for the intended design parameters and to offer life extension considerations.

- Fatigue analysis to calculate the fatigue life of heat exchangers subjected to pressure cycles, temperature cycles and startup / shutdown cycles.

- Failure Analysis to identify the root cause of failure for the failed heat exchangers or heat exchanger components.

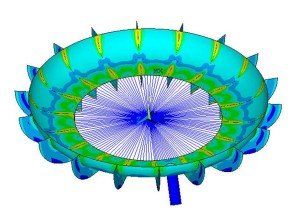

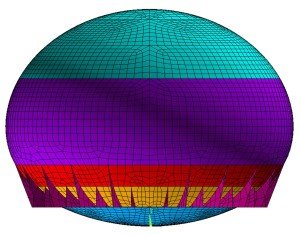

- Finite Element Analysis for heat exchangers or heat exchanger components.

- Heat exchanger certification, calculations and rating / re-rating for heat exchangers that do not contain sufficient design information in their files.

- Evaluation of Heat Exchangers after accidental over-pressurization.

- Analysis to assure Mechanical Integrity of Heat Exchangers for following type of flaws: Generalized corrosion, Localized corrosion / Thinning, Blisters, Laminations, Bulges, Gouges, Dents, Cracks etc.

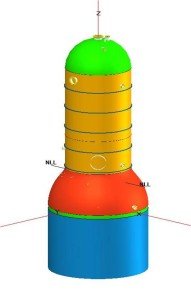

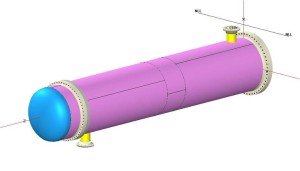

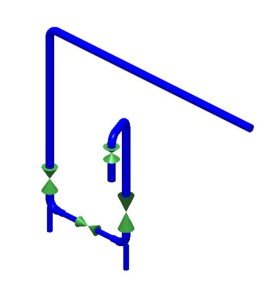

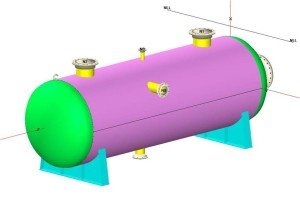

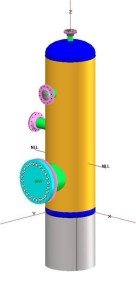

Here are some examples of Heat Exchangers Design / Analysis performed by Pressure Equipment Engineering Services.