The minimum retirement thickness values for existing pressure equipment (pressure vessels, pressure vessel components, heat exchangers, heat exchanger components etc.) are generally calculated for internal and external pressure considerations and are generally known as “Pressure Min T”. It is equally important to note that these thickness values should not be less than the minimum retirement thickness based on structural engineering considerations (also known as “Structural Min. T”). The actual minimum retirement thickness specified is the greater of “Pressure Min T” and “Structural Min. T”.

The minimum retirement thickness values for existing pressure equipment are calculated to maximize the remaining safe and useful life. The minimum retirement thickness for a pressure component is used as input into the Inspection program (like Ultrapipe) to calculate the remaining life and the inspection interval based on half life criteria. This key information is used to schedule inspections and to keep the existing pressure equipment safe. This also acts as basis for certain repairs.

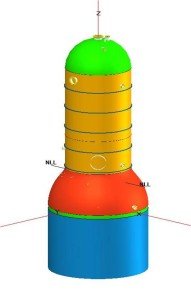

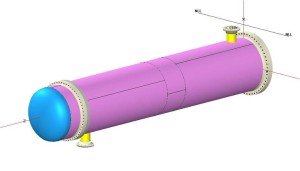

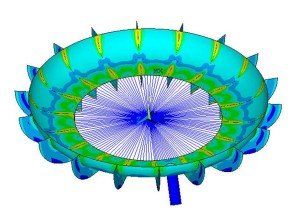

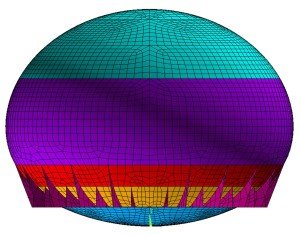

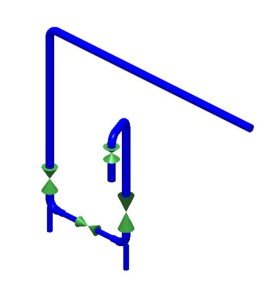

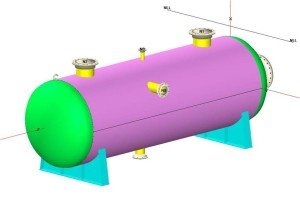

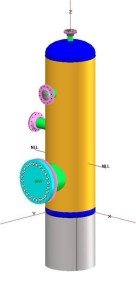

Here are some examples of Minimum Retirement Thickness Calculations performed by Pressure Equipment Engineering Services, Inc.